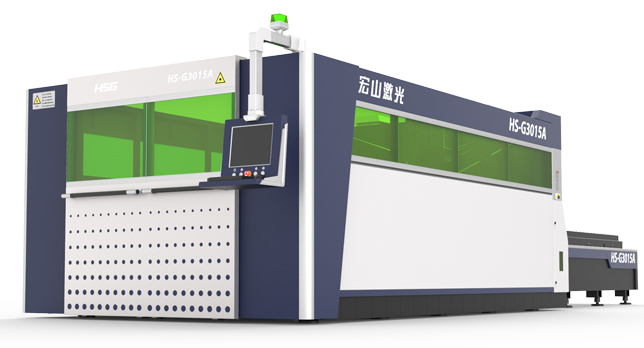

GA Series

HS-GS3015A

Sheet Metal Cutting Fiber Lasers

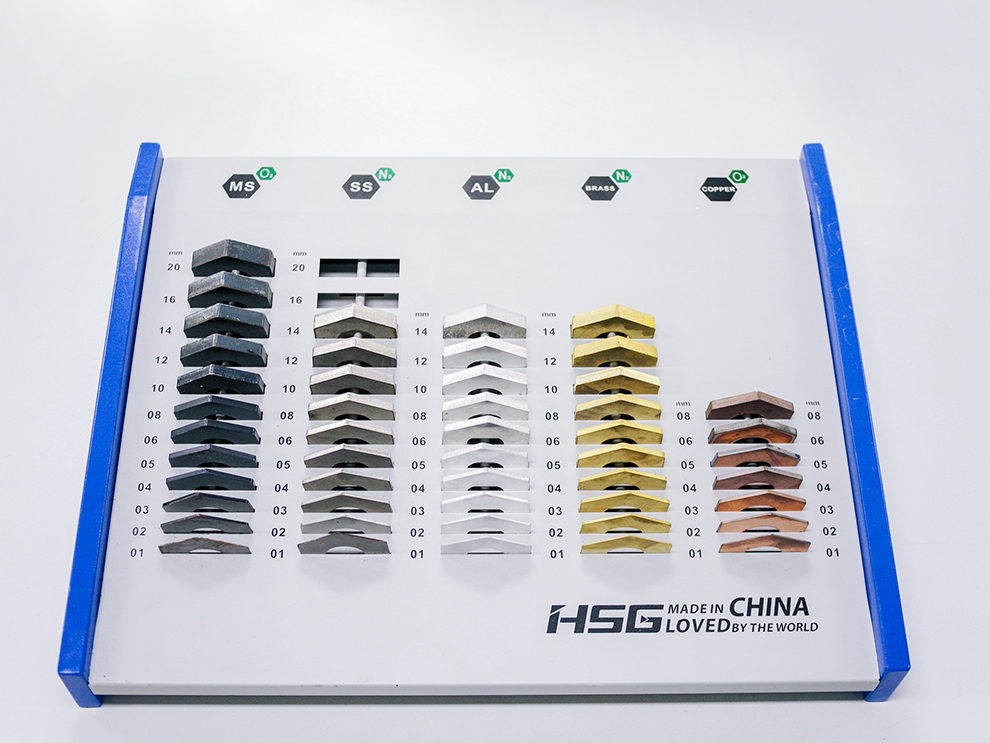

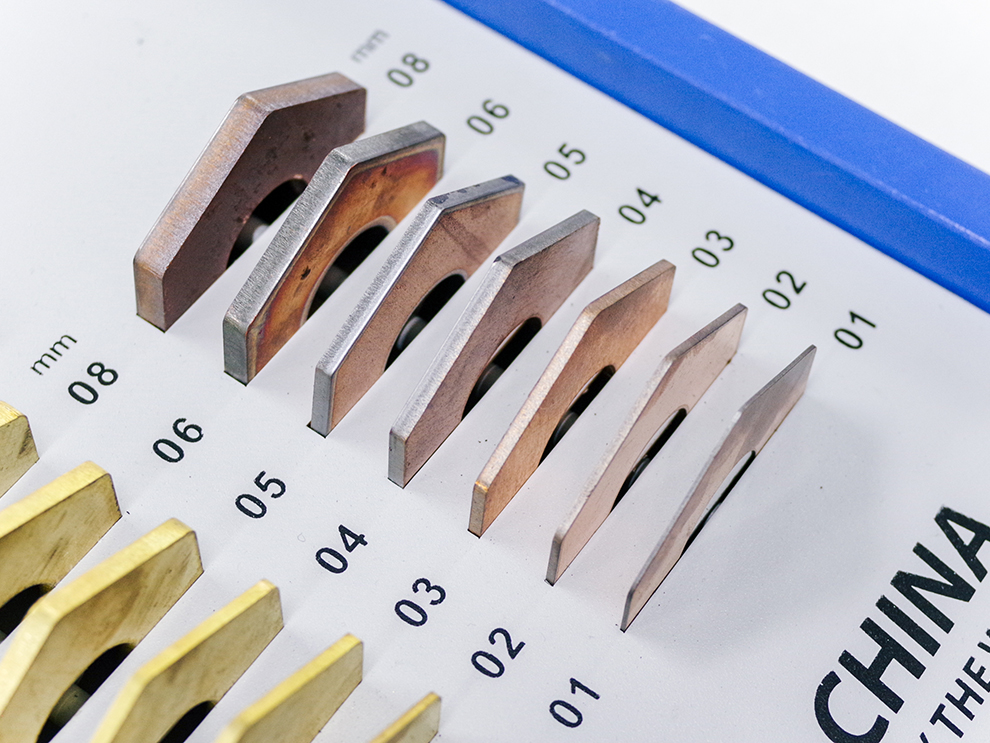

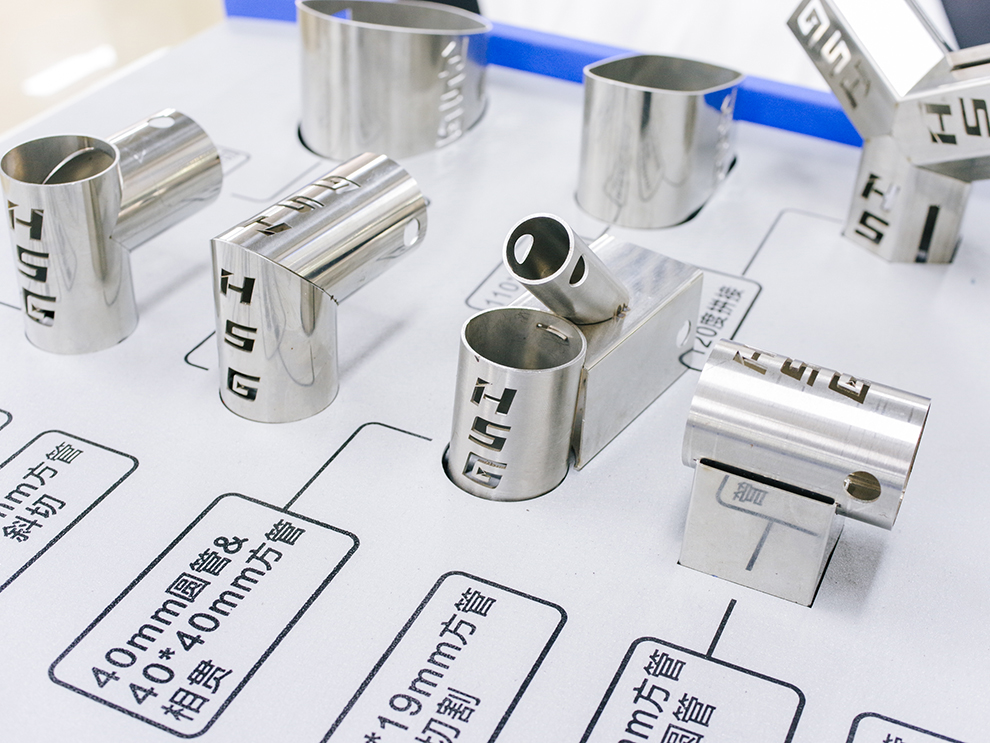

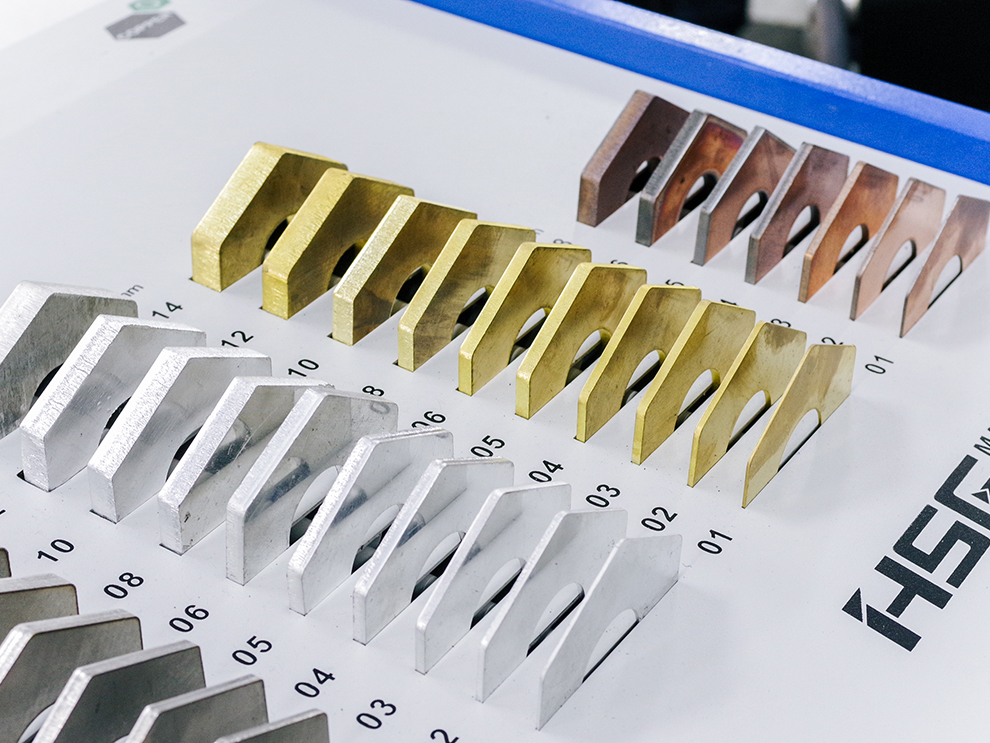

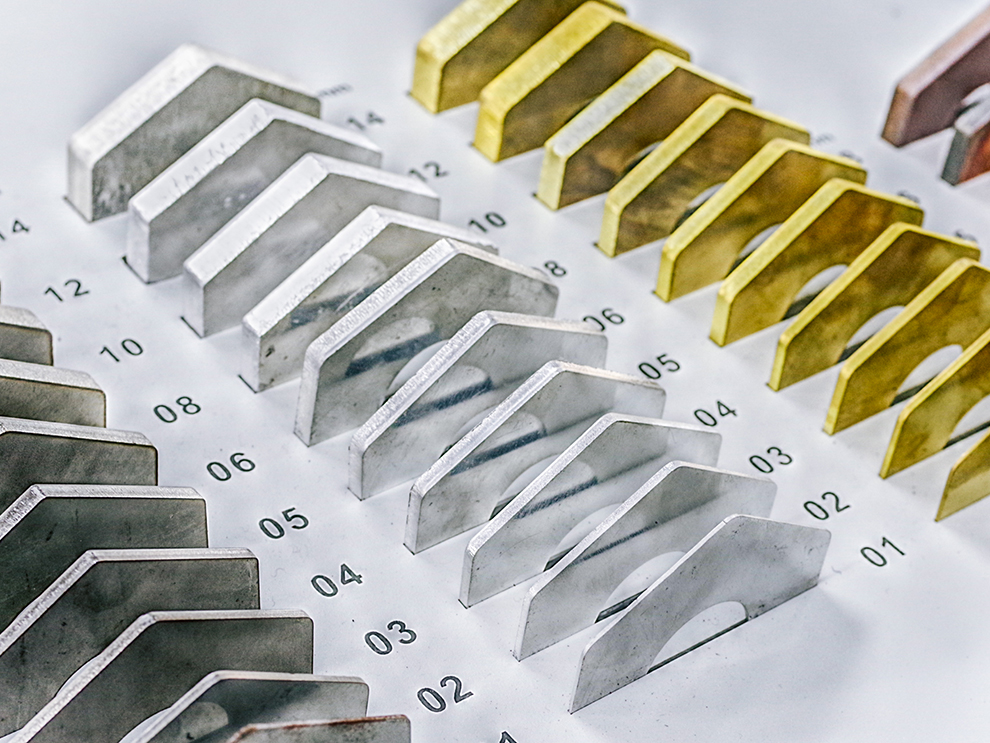

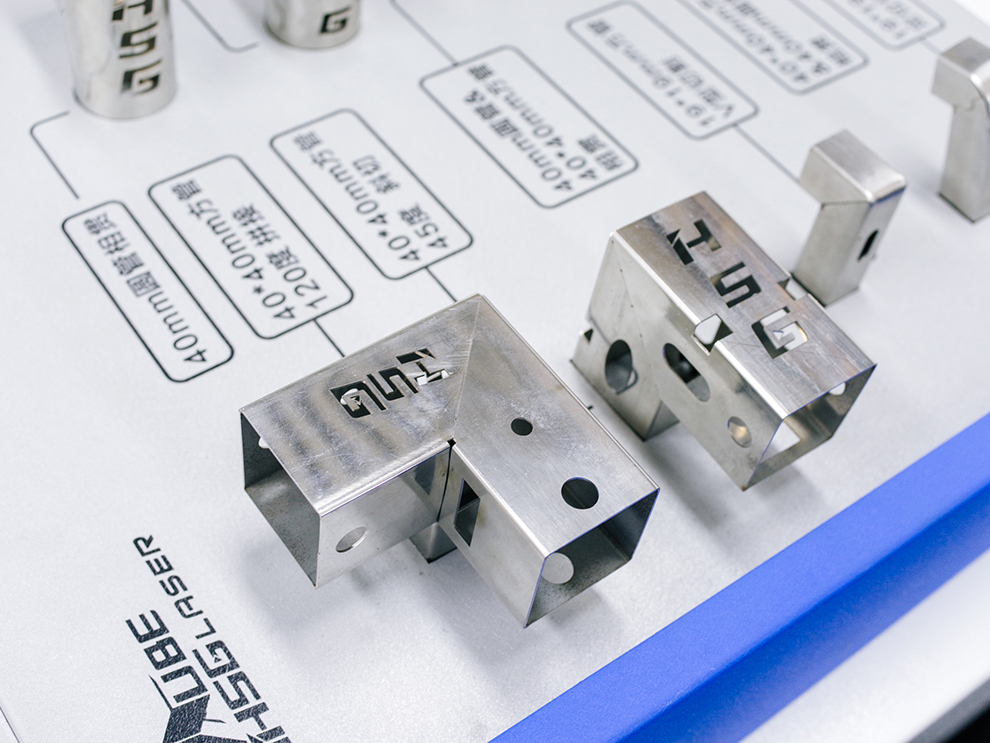

Specially used for cutting 0.5-20mm carbon steel, 0.5-10mm stainless steel, 0.5-6mm brass, 0.5-10mm aluminum, 0.5-4mm copper, as well as galvanized steel, electrolytic steel and silicon steel etc (thicknesses are related to the kinds of materials and fiber source power)

HS-GS3015A

Features

Precision Machined Frame Provides Solid Core

Welded and stress-relieved steel frame houses the machine and pallet shuttle. Dual servo drive on the X-axis permits high acceleration and speed.

Sanyo Denki Servo Motor

Equipped with Japanese Sanyo inertia servo motor, high transmitting precision.

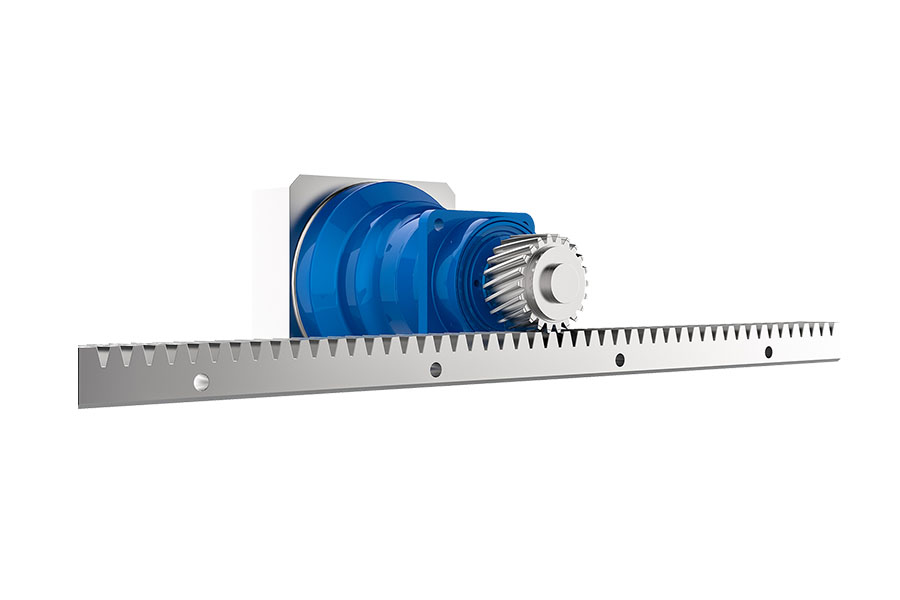

High-precision Rack And Pinion Drives

HSG Laser adopts world-renowned Alpha Wittenstein racks and gear reducers, the same product used in Trumpf machines.

HS-GS3015A

Configuration

- MAX. ACCELERATION SPEED 1.2G

- 8 SECONDS EXCHANGE TABLE

- MAX. MOVING SPEED 100M/MIN

- AUTOMATICALLY FOLLOWING MATERIAL FLATNESS TO CUT

- AUTOMATIC EDGE SEEKING

HS-GS3015A

Video

HS-GS3015A

Technical Parameters

| Processing Area: | 3000mmX1500mm |

| Max. Cutting Speed: | 140m/min |

| Max. accelerated: | 1.2G |

| X/Y Positioning Accuracy: | 0.05mm/m |

| Power supply: | 380V 50Hz |

| Available power: | 1000W-3000W |

| Gross power: | 10KVA (not include fiber laser generator or water chiller) |

| Machine Running Temperature: | 0℃-40℃ |

| Running humidity: | <90% |

| Whole machine weight: | 7500kg |

| Machine dimensions: | 8500X2900X1900mm |

| Transmission: | Precise pinion and rack,dual-drive transmitting |

HS-GS3015A

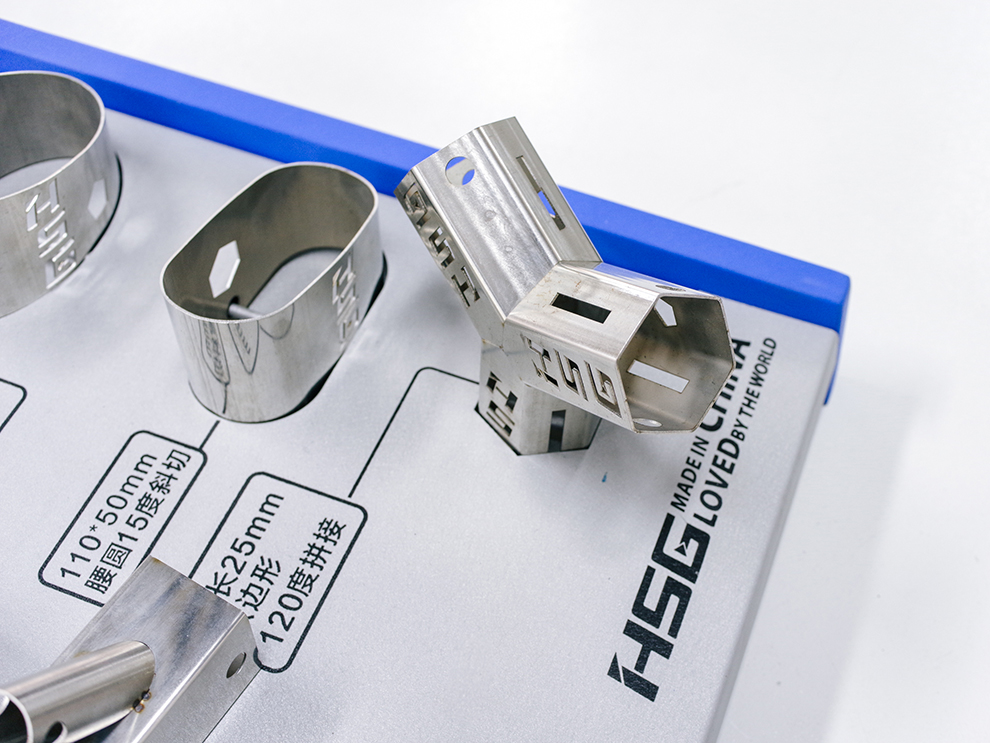

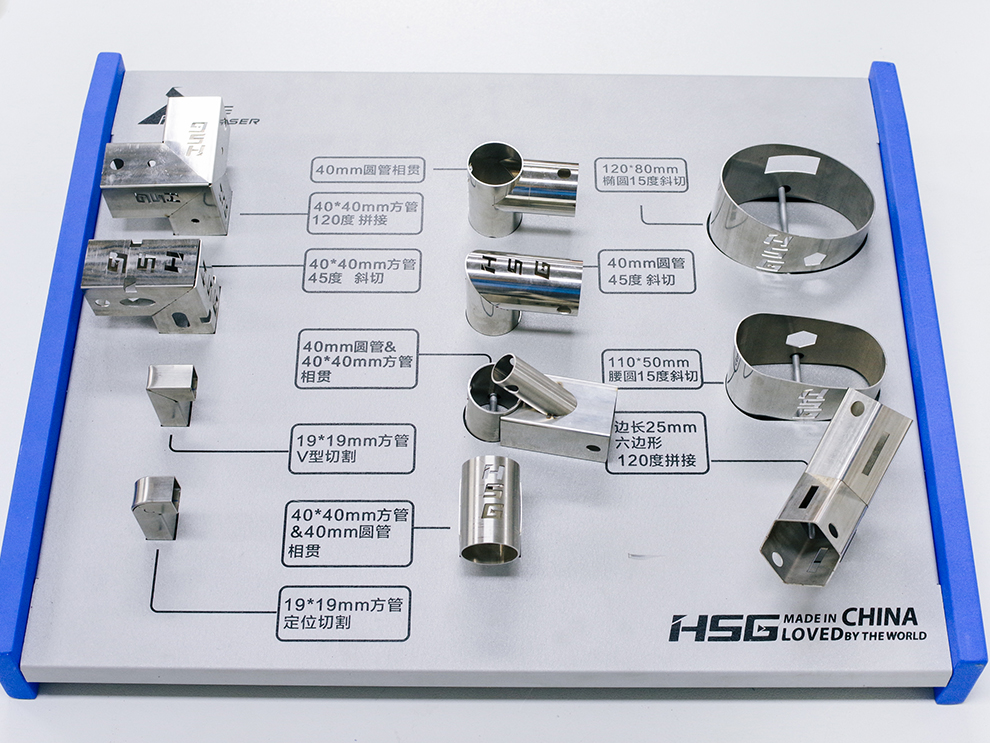

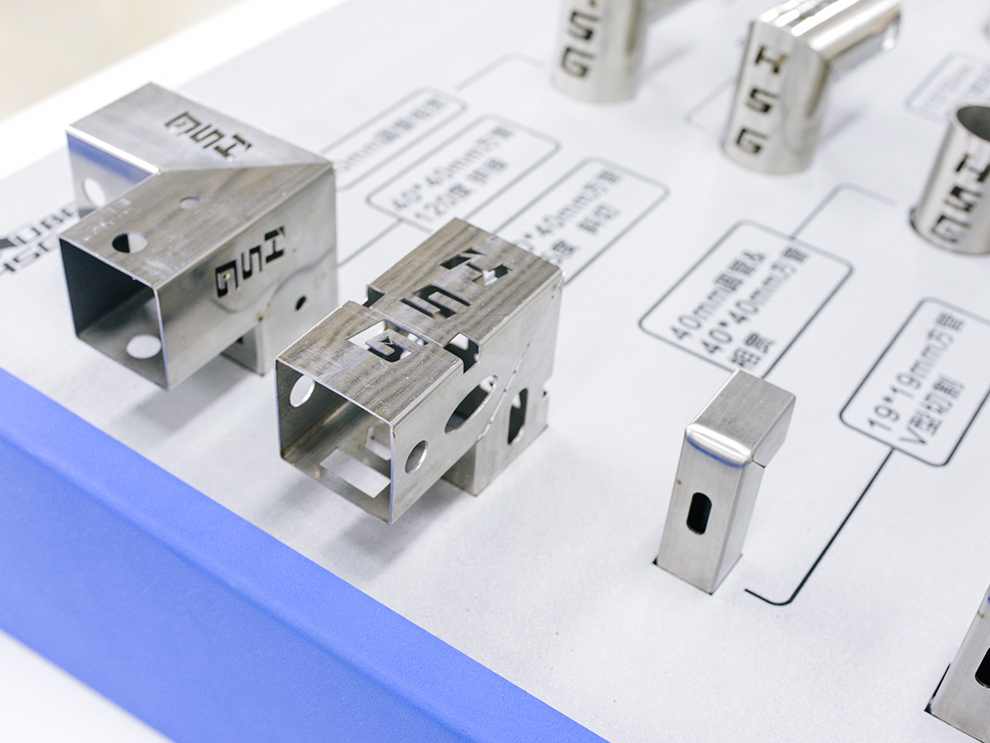

Samples

HS-GS3015A

Inquiry Form

© 2016 Paramount Machinery Inc. All rights reserved.